Does Safety Stock Just Mean Poor Forecasting? A Deeper Dive into Inventory Risk

Explore whether safety stock is a sign of poor forecasting or a smart buffer against uncertainty. Learn how to balance risk, demand variability, and supply chain resilience.

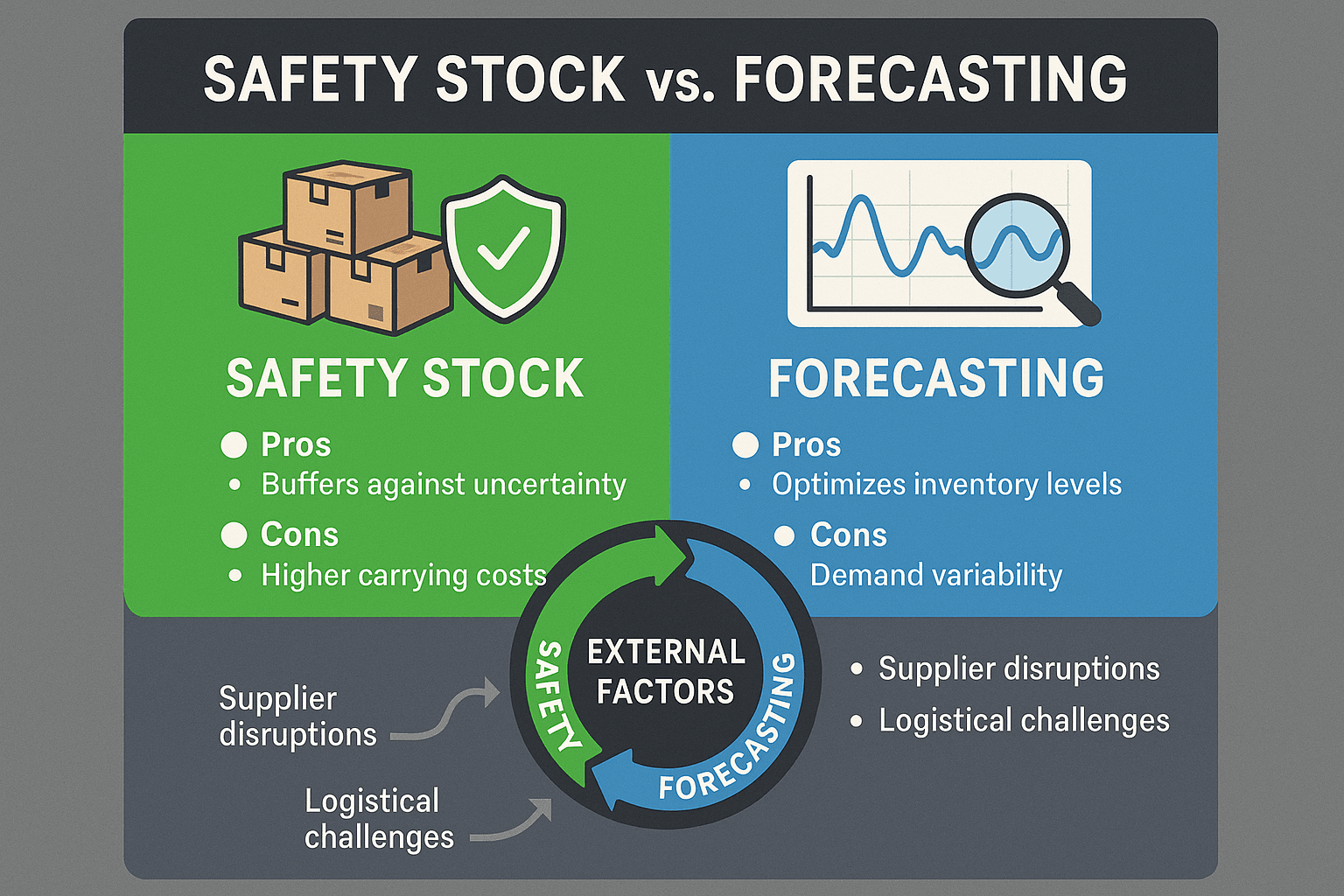

The role of safety stock in inventory management is a frequent topic of debate. While often seen as a primary solution for mitigating inventory risk, some argue that excessive reliance on safety stock can mask underlying issues in forecasting and lead to inflated holding costs.

The Case Against Over-Reliance on Safety Stock

One perspective suggests that large safety stock levels are indicative of insufficient forecasting. When forecasting is robust and accurately accounts for lead time variability, the necessity for substantial safety stock diminishes significantly. The argument is that superior forecasting capabilities can often outperform the strategy of simply piling on more inventory, as extra buffers can obscure genuine demand signals.

The Counter-Argument: Why Safety Stock Remains Essential

However, it's crucial to recognize that safety stock is more than just a band-aid for forecasting inaccuracies. It's a carefully calculated planning parameter, influenced by a multitude of inputs. It serves as a critical buffer against unforeseen circumstances that even the most advanced forecasting models cannot predict. Consider scenarios like:

- Supplier Business Interruptions: Unexpected events, such as natural disasters or labor disputes, can disrupt a supplier's operations.

- Logistical Challenges: A truck breakdown or other transportation issues can delay deliveries.

- Unpredictable Events: While forecasting aims to predict future demand, it can never be 100% accurate. "Stuff happens" that is simply impossible to forecast, and safety stock provides a crucial safety net when forecasts miss the mark.

Ultimately, safety stock represents a delicate balance between the cost of holding inventory and the cost of a stock-out. It's not a singular solution but a vital component of a comprehensive inventory management strategy, acknowledging that even with the best forecasting, the unexpected can and will occur.

Beyond Forecasting and Safety Stock

The discussion around inventory management extends further, encompassing strategies like build-to-stock versus make-to-order, flow principles, Theory of Constraints (TOC), and Just-In-Time (JIT) methodologies. These approaches offer alternative perspectives and solutions that can complement or even, in some contexts, be considered superior to solely relying on forecasts and safety stocks.

The question remains: Do you lean more on sophisticated forecasting, or do you still view safety stock as the more secure option in managing inventory risk?