How to Keep Track of Consumables

Learn how to master consumable inventory management to prevent stockouts and costly slowdowns. This guide covers how to centralize data, implement a perpetual inventory system, align reordering with tracking, and more.

How to Master Consumable Inventory Management

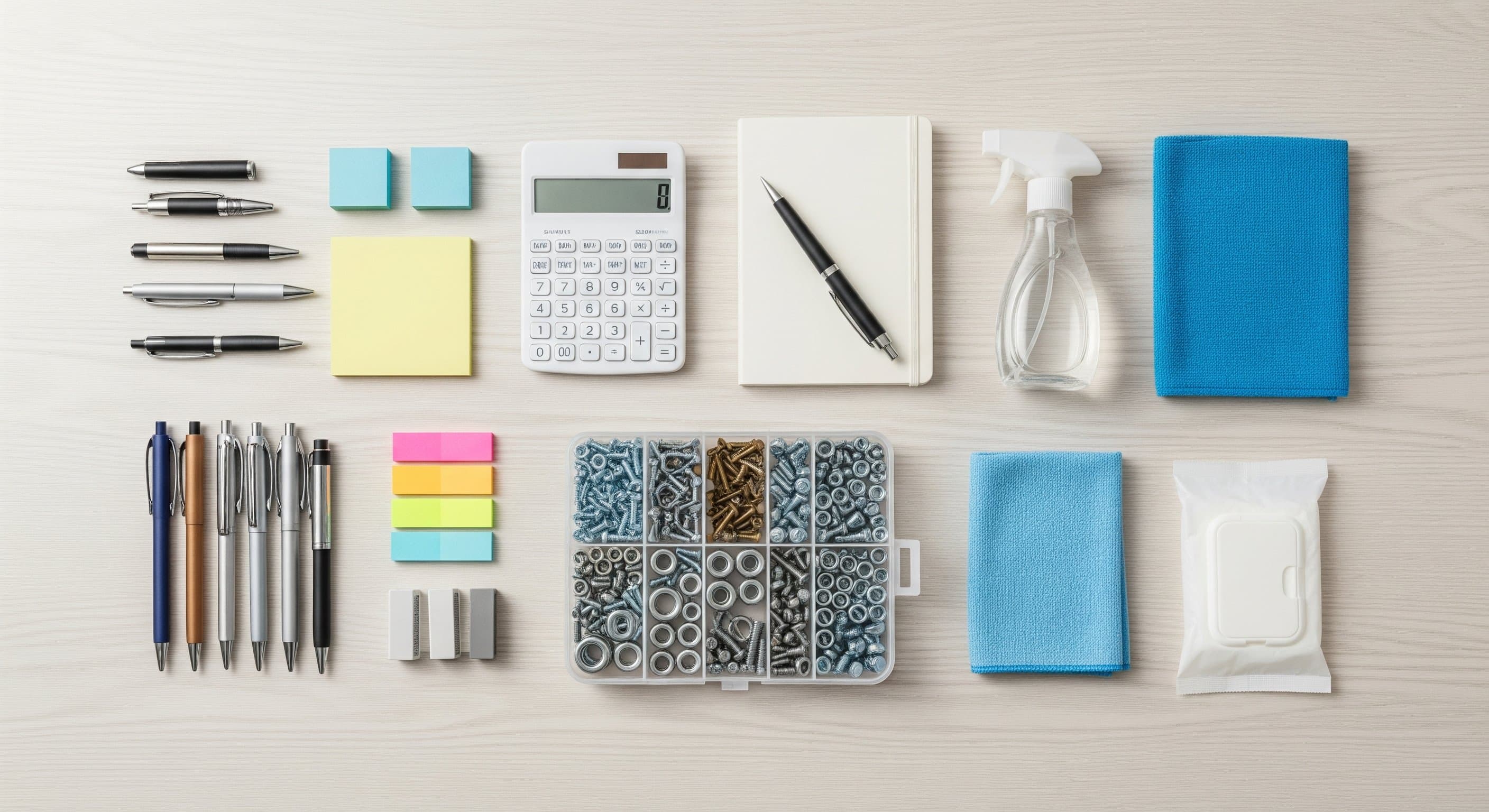

Consumables—the everyday items that power your business—are critical to productivity and profitability. From office supplies to raw materials, keeping these short-lifespan items in stock is essential. This guide will walk you through the basics of managing consumables to prevent costly slowdowns and optimize your operations.

What is Consumable Inventory?

Consumables are items your business uses up to create products or deliver services. Unlike products you sell, these items are designed to be consumed.

Examples:

- Office: Printer paper, pens, sticky notes.

- Construction: Nails, screws, lumber.

- Service: Cleaning supplies, fuel, paper towels.

While product inventory tracking is often a top priority, neglecting consumables can directly impact your bottom line through work stoppages and last-minute, expensive purchases.

Five Steps to Track Consumables Effectively

1. Centralize Your Data with the Right Tool

The first step is to create a comprehensive list of every consumable your company uses. Instead of relying on paper or spreadsheets, use an inventory management system. Your inventory list should include:

- Item name and description

- Current quantity and minimum quantity

- Location

- Purchase price and value

- Unique identifiers like SKUs or barcodes

Using a dedicated system allows you to easily track, update, and manage this information in one central location.

2. Implement a Perpetual Inventory System

A perpetual inventory system provides a real-time view of your stock. Each time an item is used or moved, the system is immediately updated. This eliminates the need for manual, time-consuming counts and offers significant benefits:

- Accuracy: You always know exactly how much of an item you have on hand.

- Efficiency: Your team can move items and plan ahead with confidence.

- Clarity: It streamlines communication across teams and locations, ensuring everyone has the same information.

3. Align Your Tracking with Reordering

To prevent stockouts, your tracking system must inform your reordering process. Use data to calculate key metrics that tell you exactly when and how much to reorder.

- Reorder Point: The specific stock level that triggers a new order.

- Safety Stock: The extra inventory you hold to buffer against unexpected demand or supply delays.

- Lead Time: The time it takes for a new order to arrive.

An inventory system can automate this by setting up low stock alerts and reordering reminders, ensuring you're never caught off guard.

4. Train Your Team for Success

No system is effective without proper use. Whether you use a high-tech app or a simple spreadsheet, dedicate time to training your employees. Create a clear, sustainable standard operating procedure (SOP) that outlines how and when to track inventory. This consistency reduces human error and ensures everyone is on the same page.

5. Conduct Regular Audits

Even with a perpetual system, physical inventory audits are essential. Schedule a full count of all consumables at least once a year. This is the only way to verify that your digital records match your physical inventory. Any discrepancies can help you uncover issues like theft, spoilage, or non-compliance with procedures, allowing you to make necessary improvements.

By following these steps, you'll gain full control over your consumables, saving time, money, and ensuring your business runs without interruption.